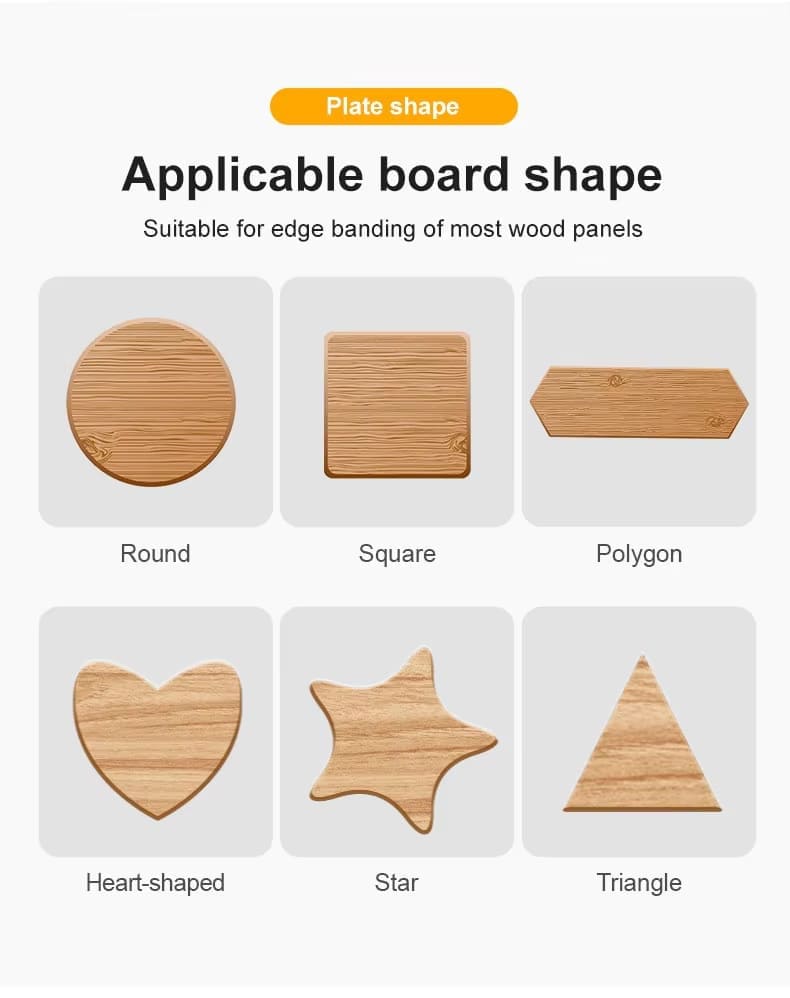

The F13-3 curve edge banding machine can operate a variety of curved plates such as rectangles and ovals. This article will introduce the F13-3 curve edge banding machine in detail. We hope it will be helpful to you.

Features:

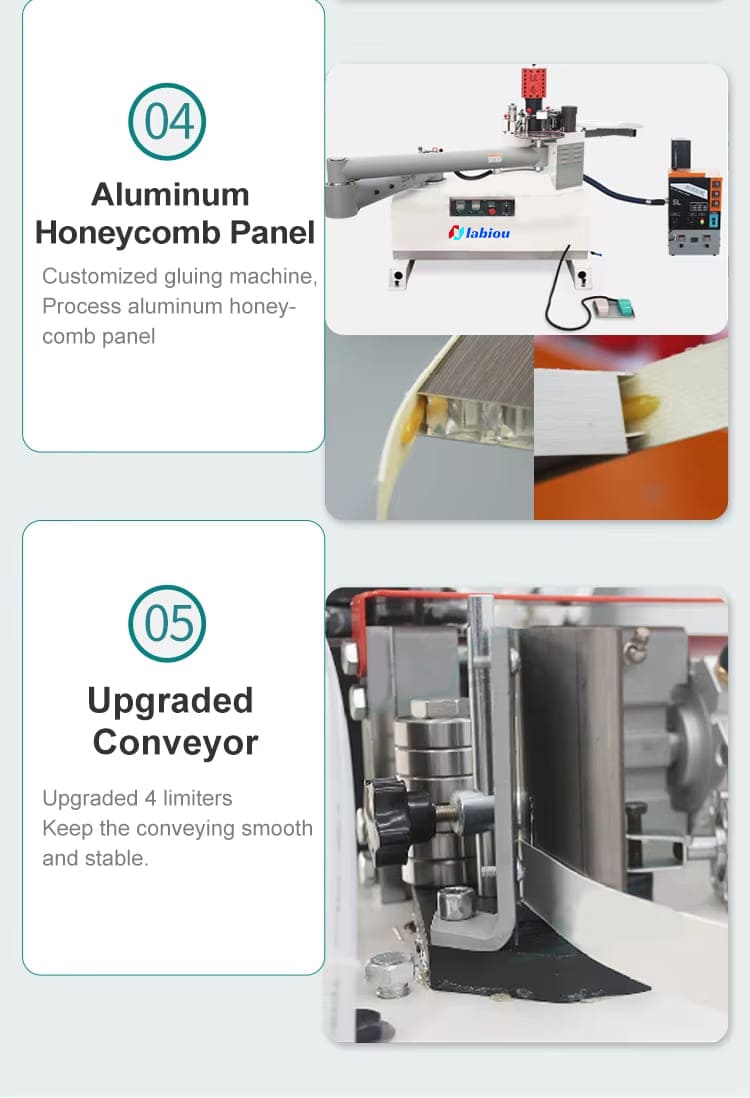

Introducing the F13-3 Curve Edge Banding Machine,This advanced machine is specifically designed to cater to the needs of curved plate edge banding, making it a versatile choice for various applications. With the ability to operate on both rectangular and oval plates, this machine offers flexibility and convenience.

·One of the standout features of the F13-3 Curve Edge Banding Machine is its impressive rotation capability. It can rotate up to ±16°, allowing for precise and accurate edge banding on curved surfaces. This ensures a seamless finish, even on complex shapes. Additionally, the machine can be equipped with an optional EVA filling glue machine, further enhancing its functionality.

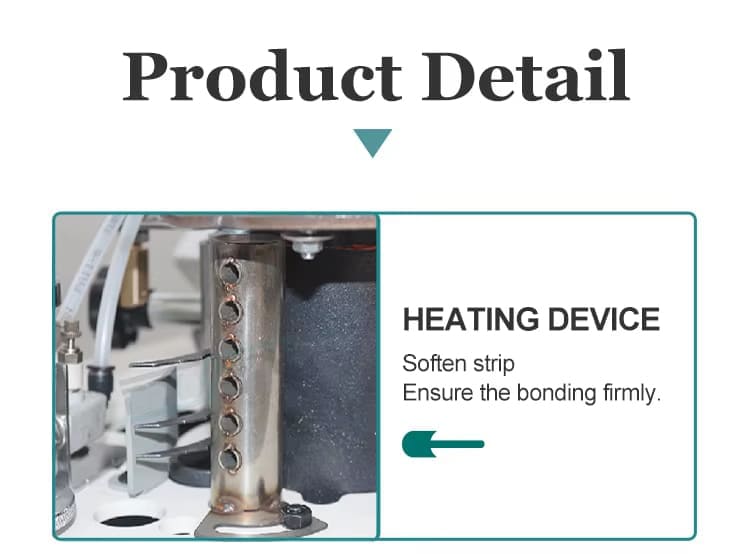

·When it comes to specifications, the F13-3 Curve Edge Banding Machine boasts a power supply voltage of AC220V/50HZ and a total power of 3.5KW. The air source pressure ranges from 0.5-0.7MPa, ensuring optimal performance. The machine supports both PUR and EVA hot melt adhesive types, with a glue pot temperature ranging from 110°C to 210°C. The glue pot has a capacity of 2600ML, providing ample supply for continuous operation.

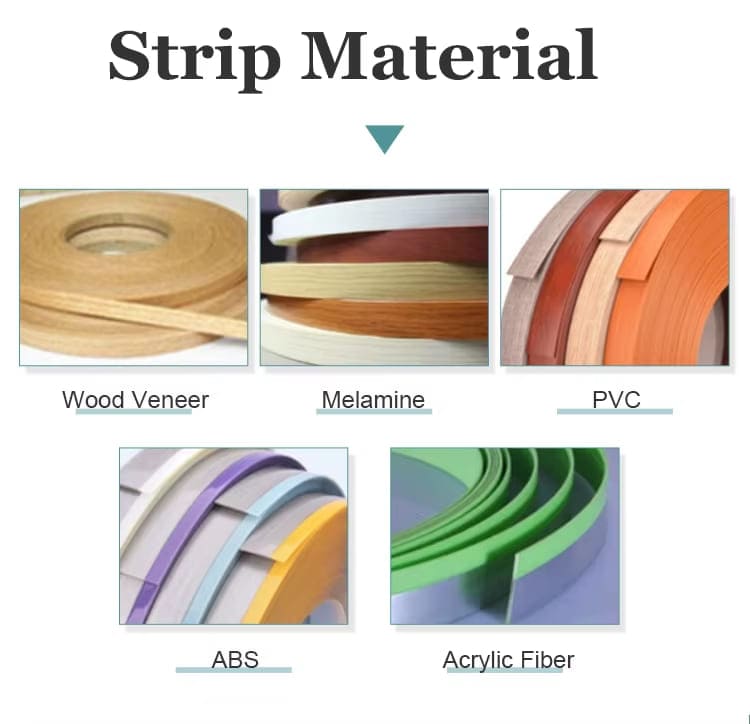

·The machine head rotation angle offers flexibility with options of 0°, +16°, -16°, and factory position. The edge banding speed can be adjusted from 4-20CM/S, allowing for precise control. The edge banding width ranges from 14-70MM, catering to various requirements. The thickness of the edge banding tape typically ranges from 0.5-3MM, depending on the material used.

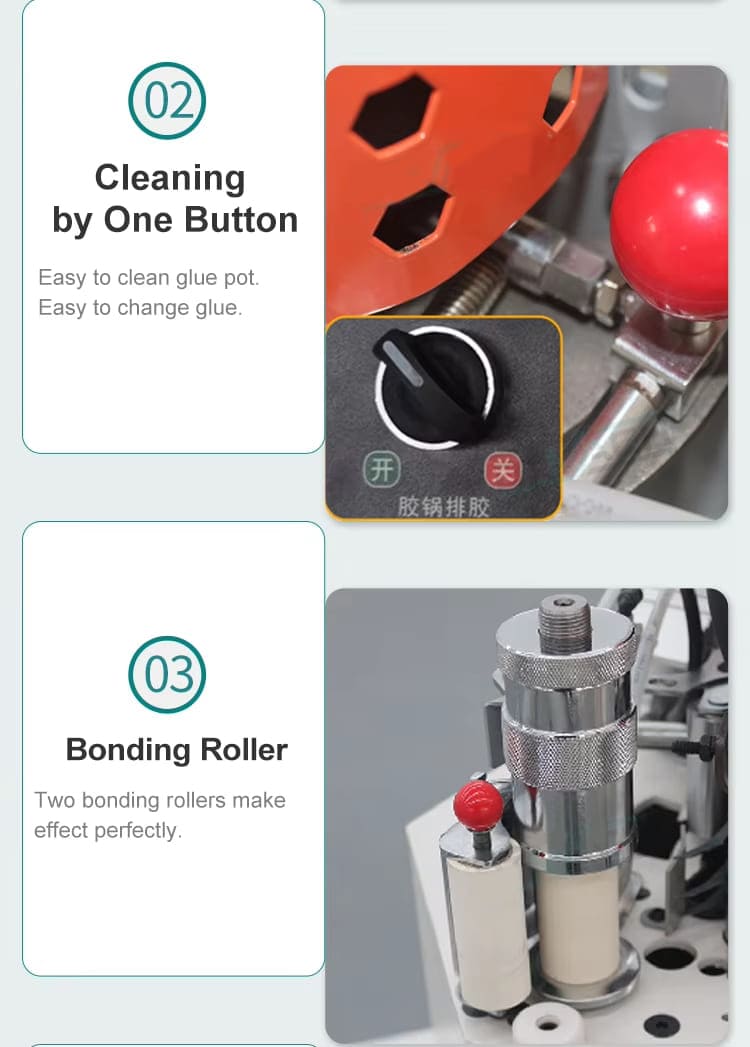

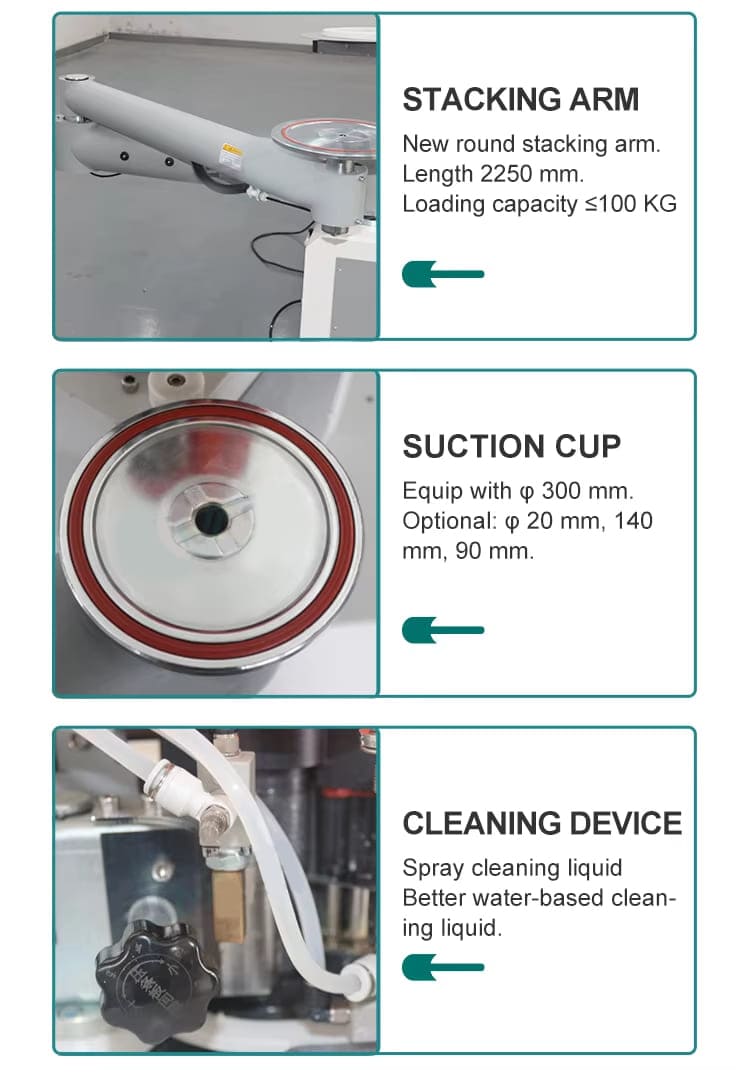

·In terms of design, the F13-3 Curve Edge Banding Machine features a circular stacked arm design that enhances load-bearing strength while maintaining a lightweight structure. The strong suction cups ensure a firm grip on the board, providing stability during the edge banding process. The machine is equipped with a dual-purpose glue pot, capable of quickly melting and releasing glue. The internal Teflon coating prevents glue hanging and accumulation, improving overall efficiency.

·Furthermore, the F13-3 Curve Edge Banding Machine incorporates an upgraded cutter assembly and dual-cylinder control system. The large cylinder controls the cutter, while the small cylinder controls the belt feeding. This ensures precise and consistent cutting, resulting in a clean and professional finish.

·With its impressive features and specifications, the F13-3 Curve Edge Banding Machine by YinTai is the perfect choice for professionals in need of a reliable and efficient edge banding solution. Its versatility, precision, and durability make it an indispensable tool in any woodworking or furniture manufacturing setting. Trust YinTai for all your edge banding needs.

Parameter:

| Model | F13-3 |

| Supply Voltage | 220V/50HZ |

| Total power | 3.5kw |

| Air pressure | 0.5-0.7Mpa |

| Rotate angle | 0°, +16°, -16° |

| Glue pot | 2600ML |

| Glue pot temperature | 110°C to 210°C |

| Thickness of sealing strip | 0.5-3mm |

| Width of sealing strip | 14-70mm |

| Weight | 320kg |

| Packing size | 1430*1330*1630mm((L*W*H) |

Leave a Review