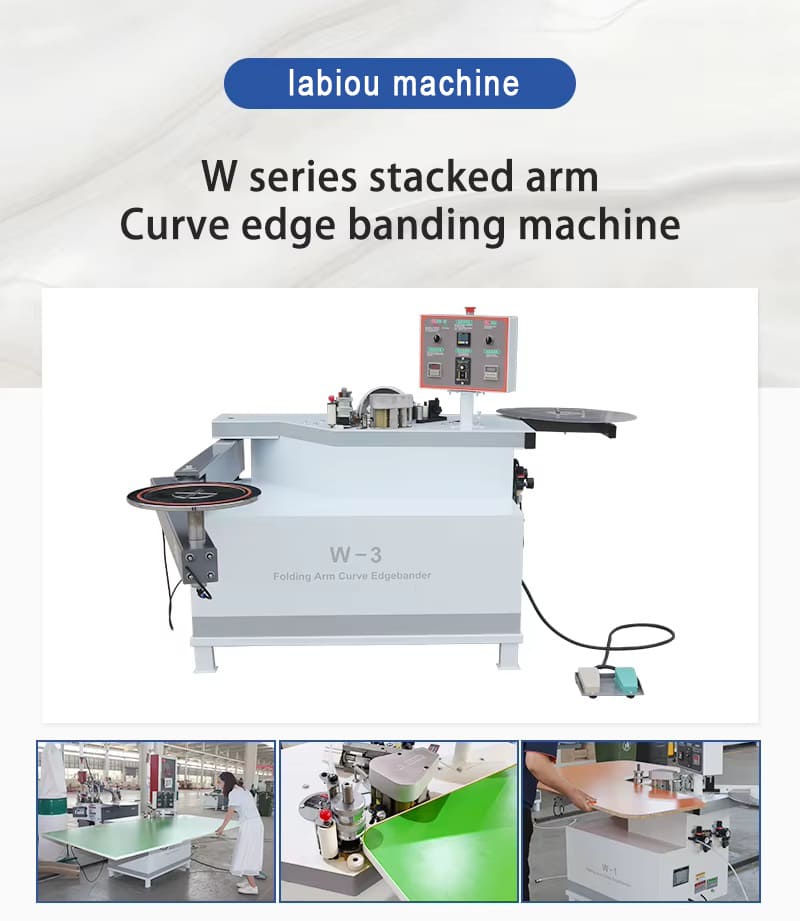

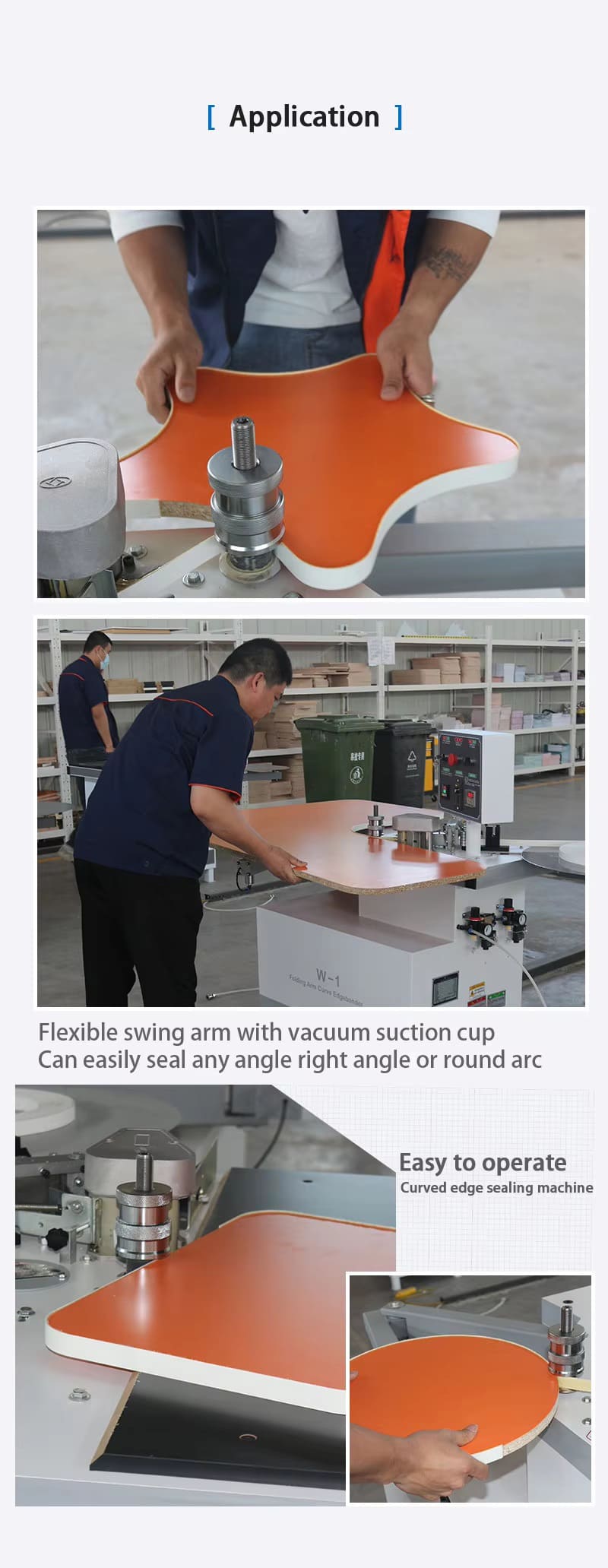

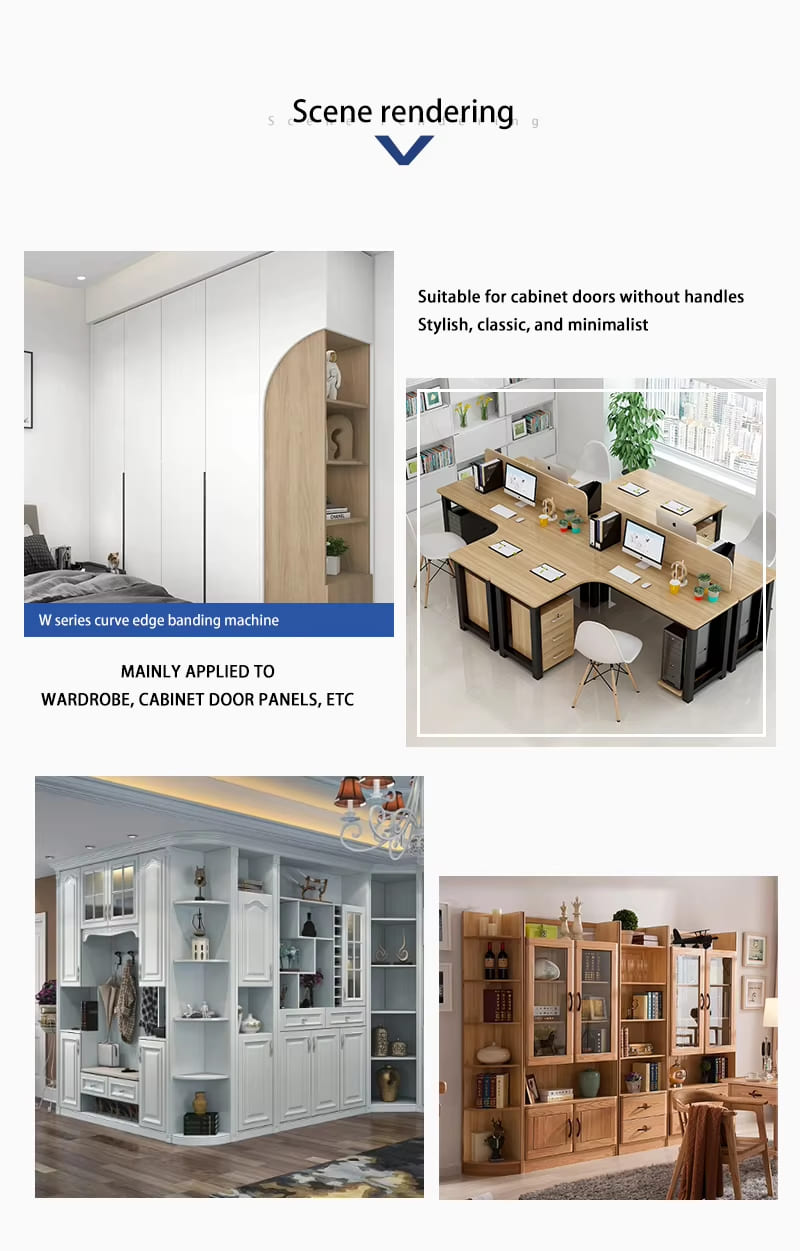

The W series curved edge banding machine can operate a variety of curved plates such as rectangles and ovals.

Features:

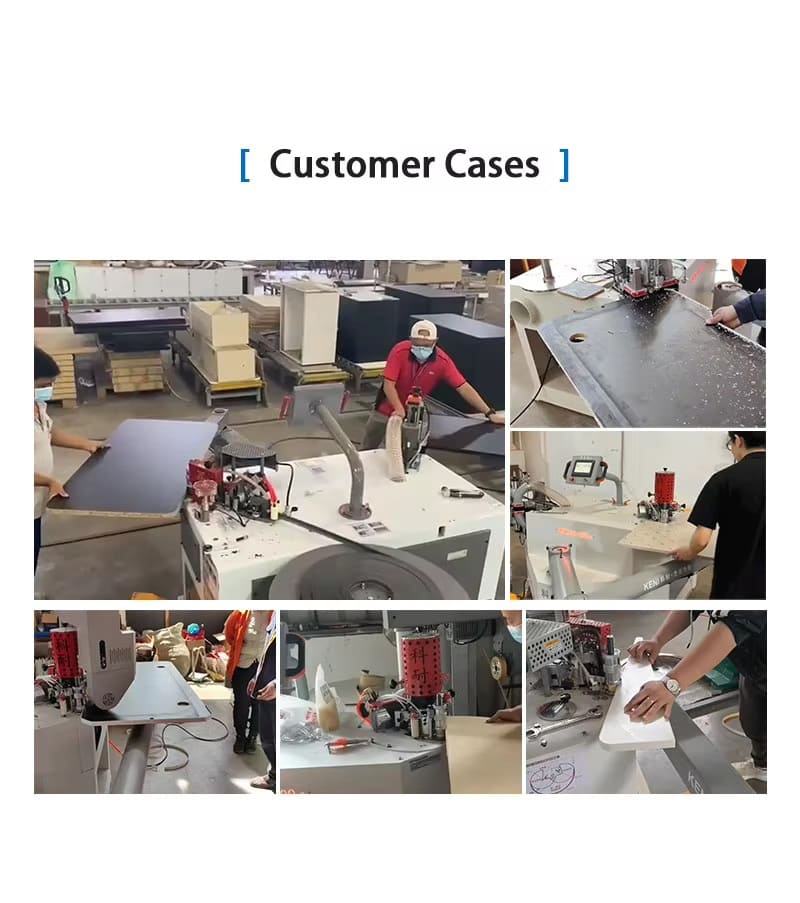

·The W series curved edge banding machine has a stacked arm design and a rotary structure. Compared with tabletop curve sealing, it is more flexible and efficient, and it is more convenient to operate large plates.

·The control panel of W series curved edge banding machine adopts well-known brand devices, digital display temperature controller, which can preset the glue temperature, timer for belt breakage, and electronic speed regulator, which can be used to adjust the button at will within the maximum value, and is precise and shockproof. , protect the power supply and prevent miss-operation.

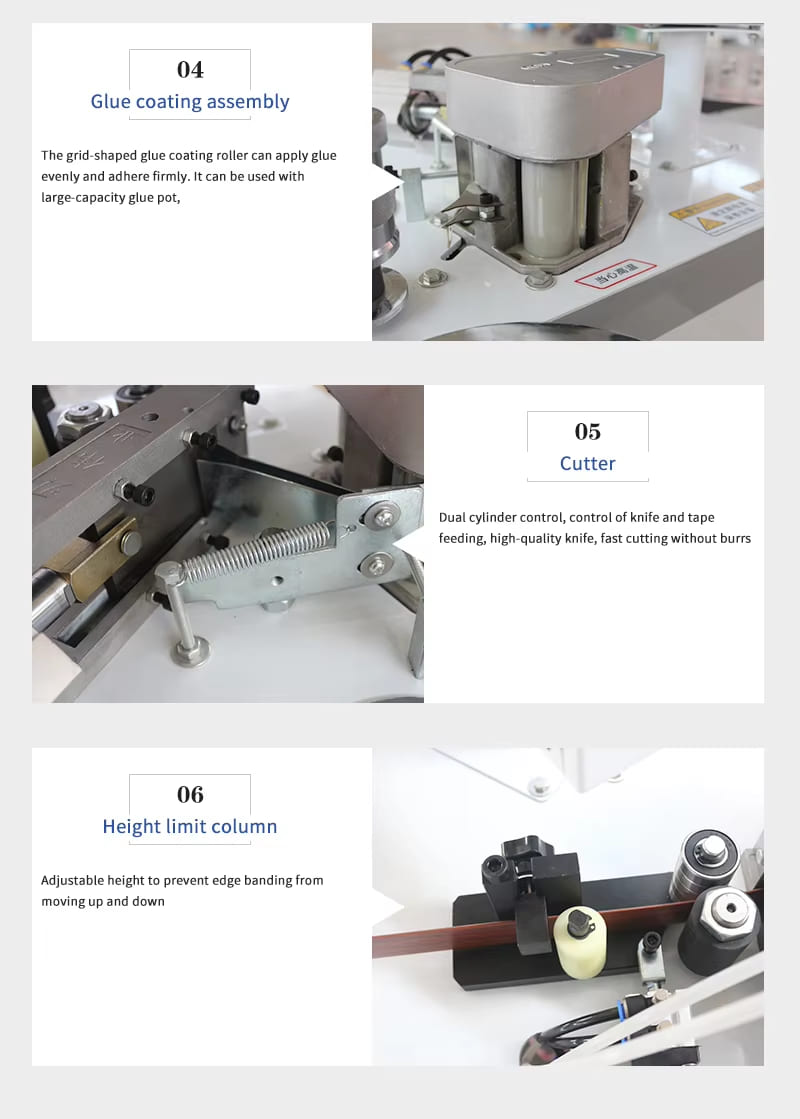

·The W series curved edge banding machine adopts a grid-shaped glue application roller, which can apply glue evenly and adhere firmly, and is equipped with a large-capacity glue pot.

·The fitting wheel and height-limiting column of the W series curved edge banding machine are adjusted according to the width of the edge banding strip, which can prevent the edge banding strip from moving up and down and reduce miss-operation.

·The W series curved edge banding machine uses dual cylinders to control the knife and tape feeding. It has high-quality tools and can cut quickly without burrs.

·The W series curved edge banding machine has a dual-pedal design. The left foot pedal controls the suction force of the suction plate, and the right foot pedal controls the edge banding strip, tape feeding and cutting.

·The small white shaft of the W series curved edge sealing is positioned so that the suction plate is parallel to the small white shaft. If the small white shaft is removed, the suction plate can be directly fixed, making it convenient to seal the small board.

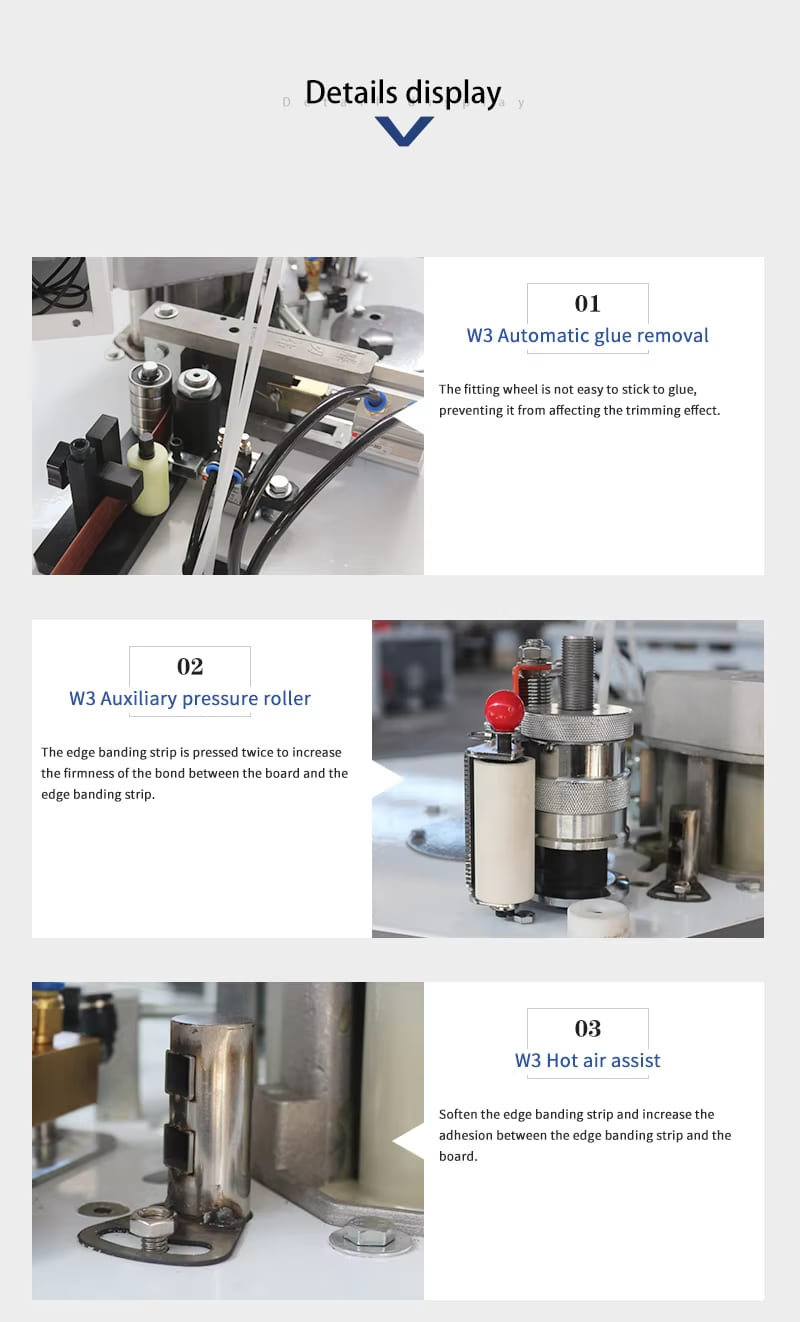

New features only for W3:

1.The W3 edge banding machine automatically cleans the glue, and the laminating roller is not easy to glue.

2.The W3 edge banding machine has an auxiliary pressing roller, and the edge banding strip is pressed twice to increase the bonding firmness.

3.W3 edge banding machine uses hot air assistance to improve the adhesion between the edge banding strip and the board.

Parameter:

| Model | W1 | W2 | W3 |

| Supply Voltage | 220V/50HZ | 220V/50HZ | 220V/50HZ |

| Total power | 1.4kw | 1.4kw | 3.4kw |

| Air pressure | 0.5-0.8Mpa | 0.5-0.8Mpa | 0.5-0.8Mpa |

| Motor power | 0.18kw | 0.18kw | 0.18kw |

| Thickness of sealing strip | 0.4-2mm | 0.4-2mm | 0.4-2mm |

| Width of sealing strip | 8-50mm | 8-50mm | 8-50mm |

| Auxiliary pressure roller | × | × | √ |

| Hot air auxiliary | × | × | √ |

| Automatic cleaning | × | × | √ |

| Weight | 145kg | 210kg | 240kg |

| Packing size | 970*850*1100mm(L*W*H) | 1300*1120*1250mm(L*W*H) | 1305*1125*1250mm((L*W*H) |

Leave a Review